Unlocking Business Growth and Efficiency Through Advanced Bulk Material Handling Solutions

In today's competitive industrial landscape, efficiency, safety, and scalability are vital components determining the success of a business. Among the myriad of operational processes, bulk material handling stands out as a crucial factor that can significantly influence productivity, cost reduction, and operational safety. As industries such as electronics and 3D printing evolve rapidly, the importance of optimized material management becomes even more pronounced.

The Significance of Bulk Material Handling in Modern Business Operations

Bulk material handling refers to the process of transporting, storing, controlling, and protecting large quantities of loose materials—such as powders, granules, and large bulk commodities. It is a core element within manufacturing, warehousing, and processing sectors, underpinning the entire supply chain. A well-designed bulk material handling system ensures seamless flow, minimizes waste, enhances safety, and reduces operational costs.

Innovative Strategies in Bulk Material Handling for Business Excellence

1. Embracing Automation and Smart Technologies

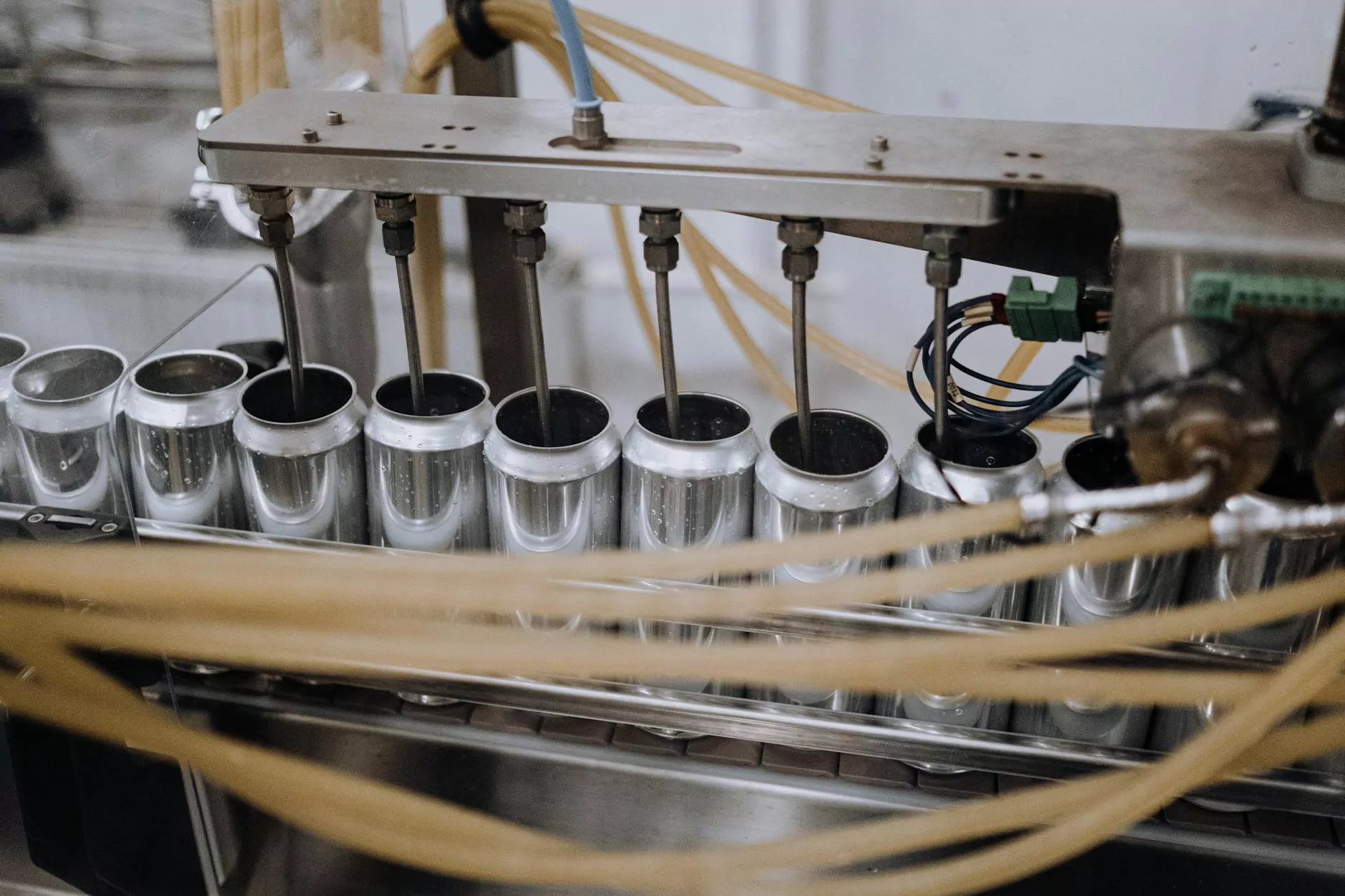

Automation has revolutionized the way bulk materials are handled across industries. Advanced systems featuring sensors, IoT integration, and real-time monitoring enable companies to control material flow precisely and predict maintenance needs, reducing downtime. Examples include automated conveyor systems, robotic loaders, and intelligent weighing modules. These innovations lead to significant increases in throughput, enhanced safety, and optimized resource utilization.

2. Implementing Modular and Scalable Systems

Modular bulk material handling solutions provide the flexibility to adapt to changing business needs. Whether expanding a facility or adjusting processing lines, modular systems facilitate quick upgrades, maintenance, and reconfiguration, saving both time and money. Scalability is especially critical in dynamic sectors like electronics manufacturing and 3D printing, where material types and processing volumes frequently evolve.

3. Prioritizing Safety and Environmental Sustainability

Safety is a paramount concern in handling bulk materials, given the risks of spillage, dust explosion, and machinery accidents. Incorporating enclosed conveying systems, dust suppression techniques, and ergonomic designs improves worker safety and environmental compliance. Sustainable handling methods, such as energy-efficient conveyors and eco-friendly materials, also enhance a company's corporate responsibility reputation and operational sustainability.

Technologies Transforming Bulk Material Handling

Advanced Conveying Systems

- Bucket Elevators: Ideal for vertical lifting of powders and granular materials.

- Drag Chain Conveyors: Suitable for high-volume, heavy-duty applications.

- Vibratory Feeders: Precise control of material flow.

Storage Solutions

- Silos and Bins: Efficient storage of bulk powders and granulates, with climate control features.

- Astral Tanks: For bulk liquids or semi-solid materials.

- Flexible Storage Silos: Modular units that can be expanded based on business growth.

Material Screening and Crushing Equipment

Enhanced screening systems separate impurities from raw materials, improving product quality in electronics and 3D printing. Crushing equipment reduces oversized particles, ensuring consistent feedstock and preventing equipment wear or clogging.

Bulk Material Handling in Electronics and 3D Printing Industries

Optimizing Material Flow for High-Precision Manufacturing

Electronics manufacturing demands stringent control over material purity and handling accuracy. Bulk material handling systems facilitate contamination-free transfer, precise weighing, and controlled dispensing of powders like silicone, resins, and rare earth elements. This precision directly impacts product quality and device performance.

Supporting Innovation in 3D Printing

The 3D printing sector relies heavily on consistent and high-quality feedstock materials. Efficient bulk material handling techniques enable the storage, blending, and delivery of specialty powders, resins, and metals used in additive manufacturing. Advanced handling solutions reduce wastage, improve layering accuracy, and support large-scale production.

Choosing the Right Bulk Material Handling Partner: PolygonMach’s Industry-Leading Solutions

When it comes to implementing bulk material handling systems, selecting a trusted partner with extensive experience and innovative technologies is essential. PolygonMach offers comprehensive solutions tailored to diverse industry needs, ensuring maximum efficiency, safety, and scalability.

- Expert Consultation: Customized system design based on specific material properties and workflow requirements.

- State-of-the-Art Equipment: Cutting-edge machinery that adheres to global quality standards.

- End-to-End Support: From installation to maintenance and upgrades, PolygonMach ensures uninterrupted operation.

The Future of Bulk Material Handling: Trends and Innovations

Integration of Artificial Intelligence (AI) and IoT

Emerging technologies like AI and IoT are enabling predictive analytics and smarter control over material handling processes. Real-time data allows for proactive maintenance, optimizing throughput, and reducing downtime.

Sustainable and Eco-Friendly Handling Practices

Solutions focusing on energy efficiency, waste reduction, and environmentally friendly materials are gaining prominence. Green technologies in conveyor belts, dust extraction, and storage design contribute to a greener manufacturing footprint.

Customization and Industry-Specific Solutions

Each industry faces unique challenges; hence, bespoke bulk material handling systems are increasingly sought after. Tailored design ensures compatibility with specialized materials, compliance standards, and processing requirements.

Key Benefits of Implementing Advanced Bulk Material Handling Solutions

- Enhanced Productivity: Faster throughput and minimized downtime.

- Cost Savings: Reduction in labor, maintenance, and product spoilage costs.

- Improved Safety: Reduced risk of accidents and exposure to hazardous materials.

- Consistent Quality: Precise control of raw material flow improves final product quality.

- Environmental Compliance: Meets stringent regulations and promotes sustainable operations.

Conclusion: Elevating Your Business with Optimal Bulk Material Handling

Efficient bulk material handling systems are not just operational necessities but strategic investments that drive business growth, innovation, and sustainability. Whether in the high-tech electronics sector or the cutting-edge realm of 3D printing, mastering material flow paves the way toward operational excellence and competitiveness.

Partnering with a leader like PolygonMach ensures access to innovative equipment, tailored solutions, and expert support, turning your bulk handling challenges into opportunities for success. As industries advance and demands become more sophisticated, staying at the forefront of bulk material handling technology is vital for maintaining a robust and future-proof business.

Take Action Today

- Assess your current material handling processes and identify areas for improvement.

- Consult with industry leaders to customize solutions that meet your specific needs.

- Invest in automation and modern technology to boost efficiency and safety.

- Stay informed about emerging trends to remain competitive in your sector.

Bulk material handling is more than just moving raw materials; it is about optimizing your entire supply chain, reducing waste, and embracing innovation. Make the strategic choice today to integrate best-in-class handling solutions and position your business for long-term prosperity and industry leadership.